RESIDENCE AMSTERDAM-NOORD

“To understand the processes in the construction sector, you have to do and experience it yourself”– Ninja Zurheide, 2019

The house on the Koopvaardersplantsoen is a well-designed head house in a row of self-build houses in Amsterdam Noord. That is special in itself. This house is extra special because we built it ourselves. So not only designed, but also built. We thought that was needed.

In our design practice we notice that the Dutch building tradition is … complicated. The process is stacked in a linear column of client – architect – main contractor – subcontractor. It makes construction rigid and difficult. Ideally the client makes a perfect List of Requirements, the architect writes a perfect specification, the main contractor gives a perfect quote with a perfect planning and the subcontractor does a perfect job. In practice it always goes wrong. The client changes his views, the architect has not drawn everything in detail, the main contractor does not receive his materials on time and the subcontractor does not show up.

But what if this isn’t a problem? What if you can organize a building process in such a way that you can actively respond to a world that is constantly changing? What if disappointments or changed insights do not make the end result worse, but better? We had had enough of having to have discussions with a main contractor, while we never got to speak to the bricklayer himself. We wanted to sit down with the construction workers ourselves, to learn something – and to be able to apply what we learned directly in construction. We wanted to build adaptively and without hassle: cheaper, more fun and better.

Bureau SLA designs offices, museums and even residential areas, but we think it is important not just to be a paper architect. That is why we have the motto: design, invent, build. For example, we designed and built a bar of materials from Marktplaats, a plastic recycling factory, with 600 schoolchildren a large glass dome at Fort Asperen and a building of borrowed items. And now: a real home.

Will it benefit if you not only draw the wall, but also stand on the scaffolding yourself? Can you learn something from the man who glues the lime blocks? We think so. Our own main contractor Ninja Zurheide knows for sure. For a year she got on her bike early in the morning – not to the studio, but to the construction site. The result is a house that could never have been built in any other way. By keeping control in the very last details, the quality is superior. And not only that: every construction professional has been able to deliver his very best work. By organizing the building site differently, you actually get different architecture.

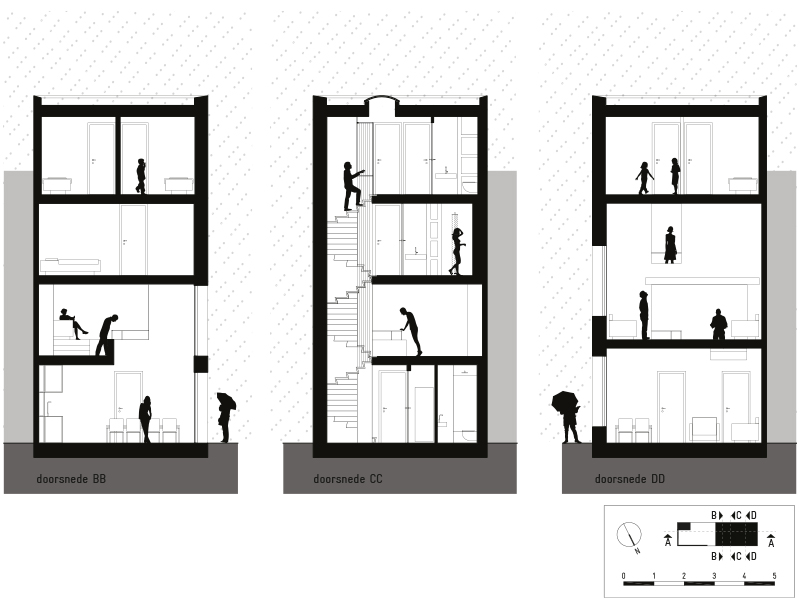

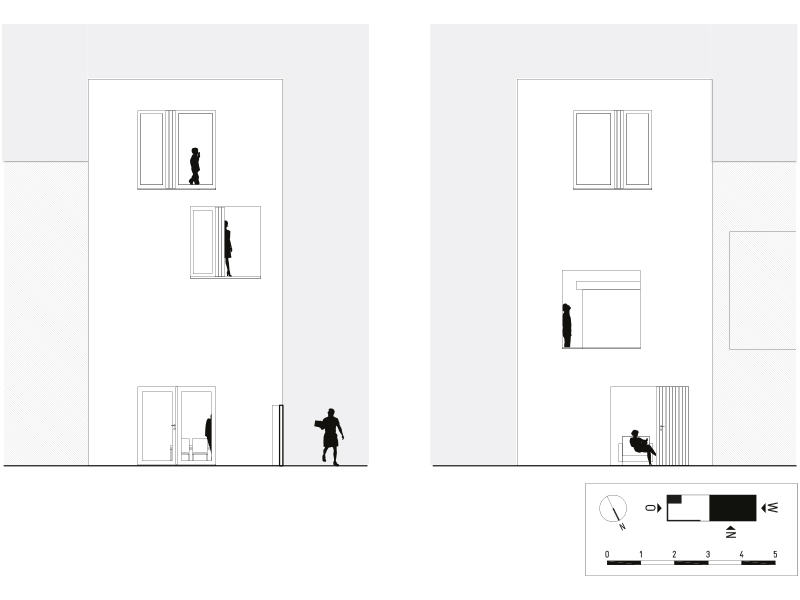

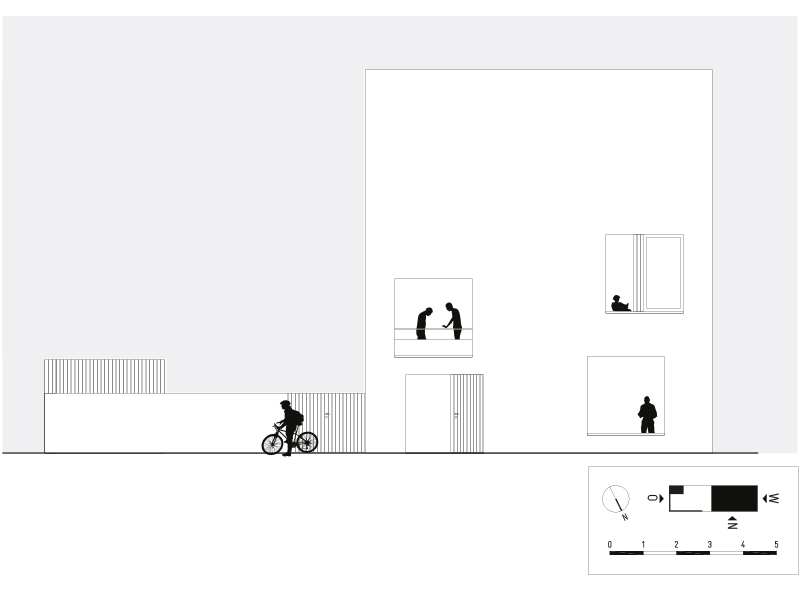

You can see this in the house. The design concept has been implemented in every detail. The house is sleek, but at the same time feels lively. A special cement mixture was invented with the bricklayer for the veiled jointing of the facade bricks. A perfect non-perfect wall finish has been designed with the plasterer. For the first time in the Netherlands, the ’tilt-and-turn’ windows fall flush with the frame, instead of being on top of it: an invention of the carpentry factory and the architect. The quality is constant and well thought out. This does not cost an extra cent, but is the result of radically re-organising the building process.

facts & figures

Design: bureau SLA

Project team: Peter van Assche, Ninja Zurheide, Alejandro Hernandez, Milad Pallesh

Main contractor: Ninja Zurheide, bureau SLA

Core team execution: Ninja Zurheide, Orson Stokvis

With special thanks to the builders